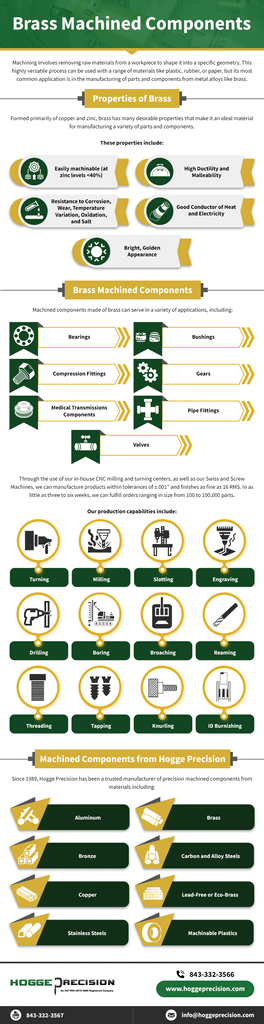

Machining involves removing raw materials from a workpiece to shape it into a specific geometry. This highly versatile process can be used with a range of materials like plastic, rubber, or paper, but its most common application is in the manufacturing of parts and components from metal alloys like brass.

Properties of Brass

Formed primarily of copper and zinc, brass has many desirable properties that make it an ideal material for manufacturing a variety of parts and components. These properties include:

Formed primarily of copper and zinc, brass has many desirable properties that make it an ideal material for manufacturing a variety of parts and components. These properties include:

- Easily machinable (at zinc levels <40%)

- High ductility and malleability

- Resistance to corrosion, wear, temperature variation, oxidation, and salt

- Good conductor of heat and electricity

- Bright, golden appearance

The machinability of brass depends on its zinc content, meaning the percentage of zinc in brass alloys must not exceed 40% in order to undergo casting, melting, punching, or other machining methods. The addition of other alloying agents like lead, manganese, aluminum, arsenic, or tin help to differentiate brass alloys while improving upon the metal’s base properties. Selecting the appropriate brass grade is a critical step in properly addressing the requirements of a specific application.

Brass Machined Components

From industrial parts and components to musical instruments, brass is used in a breadth of applications spanning numerous industries. At Hogge Precision, we specialize in machining traditional and 693 lead-free, or Eco-Brass alloys.

Machined components made of brass can serve in a variety of applications, including:

- Bearings

- Bushings

- Compression Fittings

- Gears

- Medical Transmissions Components

- Pipe Fittings

- Valves

Through the use of our in-house CNC milling and turning centers, as well as our Swiss and Screw Machines, we can manufacture products within tolerances of ±.001″ and finishes as fine as 16 RMS. In as little as three to six weeks, we can fulfill orders ranging in size from 100 to 100,000 parts. Our production capabilities include:

- Turning

- Milling

- Slotting

- Engraving

- Drilling

- Boring

- Broaching

- Reaming

- Threading

- Tapping

- Knurling

- ID burnishing

We have manufactured and delivered brass fittings, medical transmission components, and specialty valve components designed for use in the medical and plumbing industries, as well as electrical and instrument components. Additionally, we offer extensive custom machining capabilities designed to meet the specifications of any application that relies on brass machined parts or components.

Machined Components from Hogge Precision

Since 1989, Hogge Precision has been a trusted manufacturer of precision machined components from materials including:

- Aluminum

- Brass

- Bronze

- Carbon and alloy steels

- Copper

- Lead-free or Eco-Brass

- Stainless steels

- Machinable plastics

Our team has served diverse industries from aerospace and defense to construction and medical. We rely on our ISO 9001:2015 QMS registered system and employ the most up-to-date CAD/CAM technologies available to ensure precision, accuracy, and adherence to strict quality standards.

Our highly skilled technicians, combined with our full portfolio of advanced 7- and 8-axis CNC turning centers, horizontal and vertical machining centers, Swiss-style CNC screw machines, and multi-spindle screw machines, allow us to machine custom solutions to address the requirements of any project. We work closely with a network of secondary processing suppliers and offer a range of value-added services to reduce customer costs and improve productivity.

To learn more about our portfolio of brass machined components or to discover how our custom machining capabilities can serve you, contact us today.

Comments are closed