Inventory Management Overview

In addition to our extensive machining capabilities, Hogge Precision offers a range of value-added services aimed at helping our customers reduce costs and achieve maximum levels of productivity. For example, we work with customers to lessen the burden of inventory management through the implementation of Kanban inventory management practices. The Kanban system helps companies manage their inventories by minimizing the amount of product kept on hand and automating product restocking based on current demand levels.

Advantages of Inventory Management

- Cuts storage spending

- Accurately forecasts demand

- Lower risk of waste

- Optimization of production space

Inventory Management Services

There are many methods of managing inventory, each of which offers unique advantages that make it suitable for different types of businesses. The inventory management system you use can significantly affect how your business operates, which is why it is important to choose carefully.

Two of the most commonly used inventory management systems are Kanban and enterprise resource planning (ERP). Kanban was originally developed as a method of improving manufacturing efficiency. Since then, it has evolved into a method that can be used by any industry professional to manage workflows. Regarding inventory management, it emphasizes the minimization of the amount of inventory kept on hand and the automation of restocking. ERP uses various methods (e.g., min/max quantities, re-order points, usage trends, etc.) to share information, provide visibility, and improve efficiency across the business, making it easier to maintain the proper inventory levels.

At Hogge Precision, we specialize in many inventory management practices, including Kanban and ERP. We save significant time and money for our customers’ internal teams by relieving them of the burden of inventory management, allowing them to focus on critical core competencies, such as marketing and sales, product development, and production. As a service partner, we also offer a broad selection of other services—including, but not limited to, private labeling, custom bar code labeling, and returnable packaging—that support customer operations.

How Hogge Precision Implements Inventory Management Systems for Customers

We can develop an inventory management system for repeat-order account customers in any industry, including defense, power generation and distribution, heavy trucking, industrial, and medical. Many of our solutions involve the use of an ERP system. ERP systems can be used to manage all of the essential areas of a business, such as finance, human resources, supply chain management, and customer service, through a single tool. Each area has its own application, and they all share a database and communicate with one another. As a result, informed business decisions can be made much faster. Regarding inventory management, this can mean lower total lead times and improved cash-flow.

Some of the factors we consider when building an inventory management system are:

- Estimated annual usage (EAU). Knowing a repeat client’s EAU enables manufacturers to optimize production operations for efficiency, resulting in lower production costs for the manufacturer and greater cost savings for the customer. Our inventory management systems are built around 80% of the estimated volume provided by the customer.

- Minimum stocking levels. A core tenet of Kanban inventory management systems is minimized inventory. Before we develop an inventory management system, we ask the customer for their minimum stock level (i.e., what is the minimum number of an item they need to have in stock). We use this value to set up automated orders. The system will automatically send out an order request when stock falls below the preset level, ensuring the customer consistently has the inventory they need to meet customer demand.

The Advantages of Using an Inventory Management System

By employing our Inventory Management Systems, our customers experience several benefits, including the following:

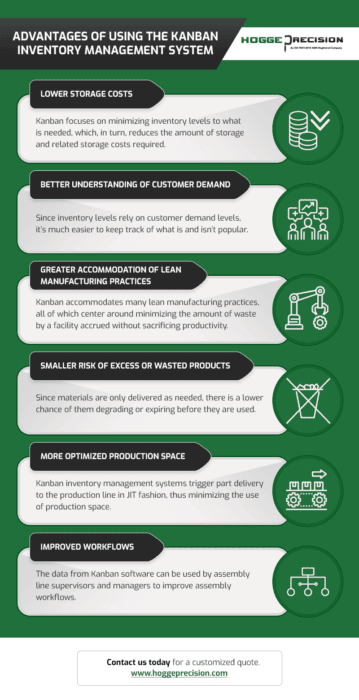

- Lower storage costs. Kanban focuses on minimizing inventory levels to what is needed, which, in turn, reduces the amount of storage and related storage costs required.

- Better understanding of demand. Since inventory levels rely on demand levels, it’s much easier to keep track of what is and isn’t popular.

- Greater accommodation of lean manufacturing practices. Kanban accommodates many lean manufacturing practices, all of which center around minimizing the amount of waste by a facility accrued without sacrificing productivity.

- Smaller risk of excess or wasted products. Since materials are only delivered as needed, there is a lower chance of them degrading or expiring before they are used.

- More optimized production space. Kanban inventory management systems trigger part delivery to the production line in JIT fashion, thus minimizing the use of production space.

- Improved workflows. The data from Kanban software can be used by assembly line supervisors and managers to improve assembly workflows.

Let Hogge Precision Help You Manage Your Inventory

As an ISO 9001:2015 Registered QMS contract manufacturer, the team at Hogge Precision strives to maintain the highest quality standards. By partnering with us for their needs, customers benefit from our commitment to providing superior products and services, a value which demonstrates itself through the following:

- Our broad range of primary, secondary, and additional services, including Kanban inventory management, private labeling, custom bar code labeling, and returnable packaging

- Our continuous improvement efforts

- Our competitive cost and uncompromising quality standards

If you require a service partner that provides all of the above and more, request a quote today.

Indicators We Use:

- Min/Max ERP Levels

- Bins

- Barcode labels

Complimentary Services:

- Private labeling

- Custom bar code labeling

- Returnable packaging

Contact Us to see how we can help you with our tailored inventory management solutions

For more than 30 years, Hogge Precision has been a leading supplier and contract manufacturer of superior quality precision machined parts and assemblies for customers around the world. Thanks to our broad range of experience and state-of-the-art, ISO 9001:2015-certified facility, we deliver top-quality products and services with exceptional attentiveness and integrity.

To learn more about our CNC milling and other machining services, contact our experts. We look forward to helping with your next project!