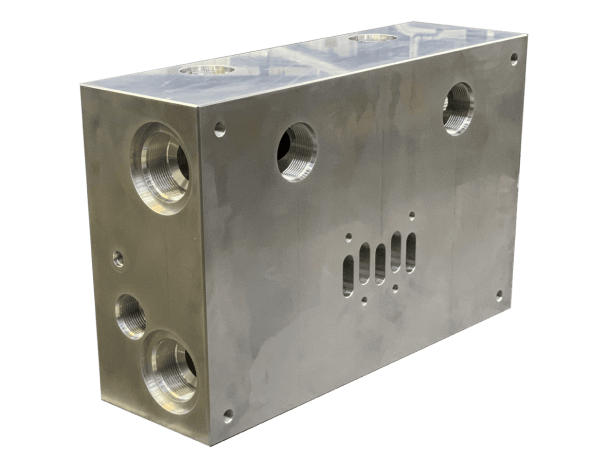

Hogge Precision offers expert CNC machining of custom aluminum manifolds for a wide range of industries and applications. As an ISO 9001:2015 registered manufacturer, we utilize state-of-the-art equipment and leverage decades of experience to produce high-quality manifold blocks tailored to your specific requirements. Manifolds are critical fluid and air distribution components – they consolidate multiple valves and ports into a single component, routing hydraulic or pneumatic flow where it’s needed. By specializing in aluminum manifold manufacturing, we deliver lightweight, cost-effective solutions without compromising strength or performance.

Benefits of Aluminum Manifold Blocks

Aluminum is often the material of choice for manifold blocks thanks to its unique advantages in air and fluid power systems. Lightweight yet strong, aluminum manifolds can weigh up to 50% less than comparable steel components, providing a significant benefit for mobile or weight-sensitive equipment. This significant weight reduction can improve system efficiency and make handling and installation much easier. Aluminum also offers excellent corrosion resistance – it naturally forms a protective oxide layer, and can be anodized for additional protection, making it suitable for use with water-based fluids or in humid environments.

Another key advantage is machinability. High-grade aluminum alloys (such as 6061-T6) are easier to machine than steel, allowing for intricate internal channels, cross-drillings, and precise threading with less tool wear. This means manufacturing costs are often lower and lead times faster, without sacrificing accuracy. Despite being lighter, aluminum manifolds still handle substantial pressures: most standard aluminum hydraulic manifold designs are rated for operating pressures up to around 210 bar (3000 psi). (For higher pressures or severe service, manifolds can be made from steel or ductile iron, but aluminum covers a wide range of needs in industrial and mobile equipment.) Aluminum’s high thermal conductivity also helps dissipate heat from flowing fluids, which can be beneficial for system cooling. In summary, choosing aluminum for your manifold provides an optimal balance of weight, strength, corrosion resistance, and cost-effectiveness for many applications.

Industries & Applications of Aluminum Manifolds

Mobile Hydraulics & Heavy Equipment:

Many agricultural machines (tractors, planters, sprayers) and construction equipment rely on aluminum hydraulic manifold blocks to control cylinders and motors. The lighter weight of aluminum is crucial for mobile machinery, as reducing weight enhances efficiency and increases payload capacity. For example, in a forklift or excavator, an aluminum manifold can host multiple cartridge valves to direct hydraulic flow without adding unnecessary mass.

Industrial Automation:

Factory machinery and robotics often use pneumatic and hydraulic manifolds to streamline plumbing for actuators and tooling. Aluminum manifolds mount solenoid valves and route air or oil flow in a compact unit, saving space on manufacturing equipment and simplifying maintenance. They can be found in manufacturing equipment, presses, and motion control systems, where they help reduce the number of hose fittings and potential leak points.

Oil & Gas Fluid Control:

In the energy sector, manifolds regulate the flow of fluids in processes such as drilling or well servicing. Aluminum manifold blocks are commonly used in auxiliary systems and lower-pressure applications, such as fuel or chemical distribution, where corrosion resistance and weight savings are beneficial. (For very high-pressure applications like certain drilling mud or hydraulic fracturing systems, steel or iron manifolds might be used, but aluminum suits many support systems.) In oil and gas exploration equipment, custom aluminum manifolds combine multiple flow paths to facilitate tasks such as chemical injection or pressure regulation.

Medical & Healthcare:

Precision aluminum manifolds appear in medical gas delivery systems, oxygen concentrators, and laboratory equipment. Here, cleanliness, corrosion resistance, and precision are crucial. Aluminum’s compatibility with anodization means the internal passages can be smooth and contamination-resistant, supporting the hygienic handling of fluids or gases. Medical pneumatic systems utilize manifolds to distribute air for respiratory devices or surgical equipment, benefiting from aluminum’s lightweight properties and machinability for creating small, precise channels.

Food & Beverage Processing:

Bottling and filling machines often incorporate manifolds to split and control flow to multiple fill heads. Aluminum is food-safe and can be treated to resist corrosion, making it suitable for use in flow regulation systems for beverage filling lines and food processing equipment. The manifold design ensures the equal distribution of liquids, such as drinks or sauces, into packaging lines, and aluminum’s thermal properties can help maintain the proper fluid temperature.

Aerospace & Transportation:

In aerospace, weight is at a premium, so aluminum manifold blocks are widely used in aircraft hydraulic and fuel systems for their high strength-to-weight ratio. They consolidate complex fluid routing (for landing gear, flaps, braking systems, etc.) into a single lightweight unit. These manifolds must be machined to extremely tight tolerances and often use aerospace-grade aluminum (like 6061 or 7075) to meet performance and safety standards. Similarly, high-performance automotive applications (such as racing) may use custom aluminum manifolds for fuel or oil distribution and even intake manifolds, to save weight while handling substantial pressures and vibrations.

Aluminum manifolds are used across numerous industries wherever fluids or gases need to be distributed through multiple channels or valves in a compact space.

Across all these sectors, the role of the manifold is essentially the same – to bring multiple fluid control elements together into one efficient package. By machining manifolds from aluminum, Hogge Precision helps customers achieve compact, reliable fluid power systems that are lighter and often less expensive to produce than alternative solutions.

CNC Machining Capabilities for Aluminum Manifolds

Hogge Precision’s manufacturing capabilities are ideally suited for producing custom aluminum manifolds with superior accuracy and efficiency. We employ advanced CNC milling centers (including horizontal machining centers with 4-axis capability) to machine manifold blocks on multiple sides in a single setup. This means we can mill complex internal passages, valve interface pockets, and port threads on several faces of the manifold without repositioning the part multiple times – ensuring excellent alignment and reducing the chance of error. Our CNC milling equipment can accommodate large billet or plate stock and utilizes high-speed spindles for efficient cutting. With a capacity of up to 330 tools and multi-axis functionality, we handle everything from simple manifold designs to those with dozens of intersecting holes and complex geometries.

Quality Assurance and ISO Certification

Quality is paramount when manufacturing components that will control high-pressure fluids. Hogge Precision is ISO 9001:2015 QMS certified, which means our entire process – from material procurement and machining to inspection and delivery – follows strict quality management protocols. For our customers, this translates into reliable, traceable production and consistent parts that meet specifications every time. We source high-grade aluminum (commonly 6061-T6 or equivalent) with material certifications to ensure strength and chemical composition are as required for critical applications.

Every aluminum manifold we machine undergoes thorough inspection and testing before it is shipped. Our quality department uses calibrated measurement tools and a Coordinate Measuring Machine (CMM) to verify all critical dimensions, port locations, and thread sizes on the finished manifold. By performing full 3D CMM inspections, we ensure that complex manifolds with dozens of intersecting features meet the exact design drawings and tolerance stack-ups. We also pay special attention to surface finish and flatness on mating surfaces, as these factors significantly impact sealing with gaskets or O-rings.

Hogge Precision’s commitment to quality is reflected in our performance metrics – we have achieved 99.8% compliance with our customers’ quality requirements and a 97% on-time delivery rate, even while shipping thousands of parts each year. Such consistency is possible due to our robust quality control procedures and the pride our team takes in their workmanship. We maintain detailed inspection records and can provide material traceability and certifications upon request, which is often important for aerospace, medical, and defense projects.

Additional Services and Finishing

Beyond machining the raw manifold block, we offer support for any additional processes required to deliver a finished component. Aluminum manifolds frequently receive surface treatments for enhanced performance – for example, anodizing is a common finishing step that increases corrosion resistance, surface hardness, and can add a color code to the part. We coordinate anodizing services (or other coatings like chemical conversion coat if needed) through our vetted network of finishing partners, delivering you anodized aluminum manifolds ready for assembly. If your design calls for pressed-in steel thread inserts, proprietary port plug assemblies, or specific sealing solutions, we can handle the integration of those as well. Our assembly team can install standard fittings, O-rings, seals, and even perform sub-assembly work if you need multiple components put together. For instance, in a recent project, we machined an aluminum manifold and then completed the job by assembling it with client-specified valves and performing pressure testing to verify leak-free operation. This turnkey capability simplifies your supply chain – you receive a fully finished manifold assembly that you can directly incorporate into your equipment.

We also understand that sometimes designs evolve. If you require engineering changes or a design iteration for your manifold, our CAD/CAM experts can swiftly implement updates and adjust the machining program. Thanks to our flexible manufacturing setup and skilled machinists, we accommodate design tweaks or different manifold configurations without long delays. Whether it’s adding an extra port, changing a thread size, or adjusting a mounting pattern, we work with you to refine the product until it perfectly suits your needs.

Hogge Precision is proud to be a U.S.-based manufacturer of high-quality aluminum manifolds, serving clients across the United States and globally. With over 35 years of precision machining expertise, a cutting-edge ISO certified facility, and a dedicated team, we are ready to tackle your manifold project – no matter the complexity or volume. We combine the latest CNC technology with a personalized, customer-focused approach to deliver the optimal solution for your fluid power needs.

Ready to Get Started? – Request a Quote

If you’re looking for a reliable partner to produce aluminum manifolds that meet exacting standards, contact our team today or request a quote to discuss your project. We offer competitive lead times and will collaborate closely to understand your requirements and deliver a manifold that enhances your system’s performance. Tell us about your application – we’re confident we can machine an aluminum manifold that will meet your needs and exceed your expectations. Don’t forget, we also do steel manifold machining as well. Let Hogge Precision help you streamline your hydraulic or pneumatic systems with our custom aluminum manifold machining services.