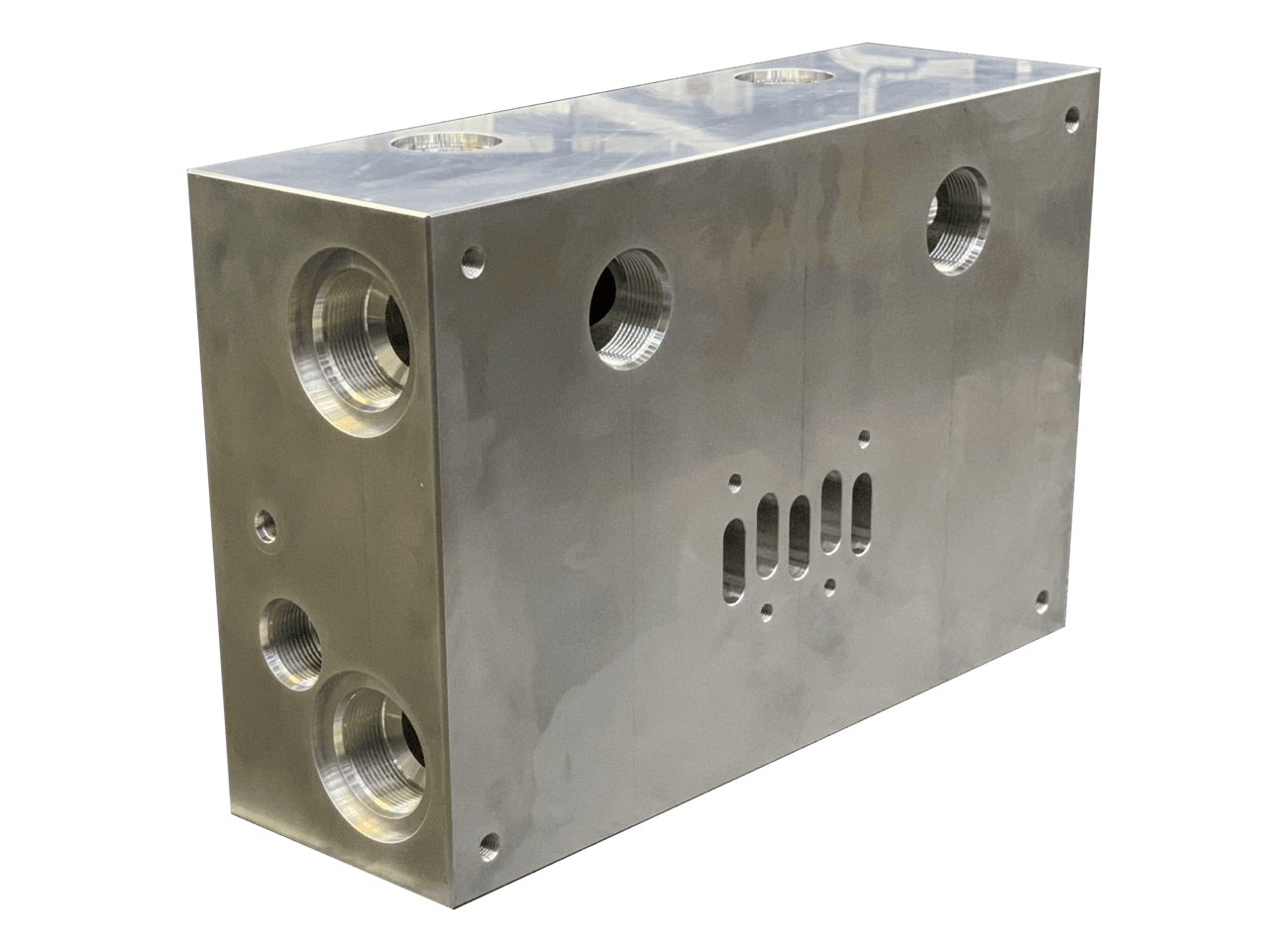

Horizontal Milling of an Aluminum Manifold for an Air Compressor

Aluminum manifolds from Hogge Precision are a practical intersection for media distribution in various fluid handling systems. By swiftly attaching pneumatic fittings to the ports, you can have several threads from a central point. Our standard aluminum manifold solution fully achieves your pneumatic control systems’ infrastructure and assembly needs.

Tightest Tolerances

Parallelism

Perpendicularity

CERTIFICATIONS

ISO 9001:2015

The Process of Horizontal Milling of An Aluminum Manifold Block

Hogge Precision serves multiple clients in advanced manufacturing. A manufacturer of air compressors requested an aluminum manifold for the medical industry. For this project, we bought all the raw materials, worked closely with the client from start to end, and offered designs for enhanced manufacturability to reduce costs. We then used our high-precision horizontal machining centers to manufacture the manifold in one complete operation. Our team concluded the process by anodizing and assembling the manifold.

The final dimensions were 15″ long, 5″ high, and 10″ wide, and it weighed 62 pounds. We manufactured the manifold from 6061 aluminum and maintained its dimensional tolerances at 0.001 for the machining operations.

We keep calibrated inspection tools on standby to measure the angle, depth, and surface features of the part. The complete manifold underwent full CMM inspection to ensure all features met the drawing specification. Within a month, we manufactured 10 manifolds for this project per the client’s requirements.

Hogge Precision is an ISO 9001:2015-certified contract manufacturer of precision-machined components.Learn about our capabilities

The Benefits of the Horizontal Milling of An Aluminum Air Manifold Block

Horizontal machining centers are ideal for manufacturing manifolds in small and large lot sizes due to the following advantages:

Speed & Efficiency: Horizontal milling machines offer some of the fastest cutting speeds, and virtually no down-time when equipped with a pallet changer making them an excellent option when time constraints are involved.

- 4th Axis: A horizontal milling machine allows the manufacturer to machine at least 3 sides of the part in one operation, reducing the possibility for errors.

- Chip Control: The machine design allows for chips to fall directly onto the chip conveyor. This prevents “re-cutting” of chips that can cause premature tool failure and poor finishes on the final product.

- Durability: Due to their large size and durable construction, horizontal milling machines have extensive working life cycles. They can handle large, heavy materials without incurring damage.

- Precision: Equipped with powerful CNC controls, these machines execute processes with high-precision tolerances (+/- 0.0005′′) and deliver high reproducibility.

Project Specs

We adhere to precise tolerances and standards by relying on our very talented machinists and cutting-edge machinery. Besides employing a horizontal machining center as the main machinery component, other key specifications include:

- Material: billets of 6061 aerospace-grade aluminum

- Tolerances: +/- .0005″

- Process Type: CNC Milling

- Applications: Hydraulic, pneumatic, valve, and manifold applications use these CNC-machined aluminum parts.

Hogge Precision Machined Components

At Hogge Precision, we focus on machine performance and best practices in delivering high-quality machined aluminum manifolds to our clients. You can also count on receiving first-class customer service, on-time delivery, and competitive production costs. Get in touch with our specialists today to learn more about how we can help with your next manifold project.

Work with Us on Your Next Project

For more than 30 years, Hogge Precision has been a leading supplier and contract manufacturer of superior quality precision machined parts and assemblies for customers around the world. Thanks to our broad range of experience and state-of-the-art, ISO 9001:2015-certified facility, we deliver top-quality products and services with exceptional attentiveness and integrity. To learn more about our CNC milling and other machining services, contact our experts. We look forward to helping with your next project!

Contact Us Request a Quote