Excellence in Aluminum Manufacturing for Over 35 Years

When your project demands precision aluminum components with exceptional quality and reliability, Hogge Precision Parts Co., Inc. delivers results that exceed expectations. Our advanced CNC machining capabilities, combined with over three decades of manufacturing expertise, position us as your trusted partner for critical aluminum machining applications across aerospace, medical, and industrial sectors.

Our commitment to excellence is demonstrated through measurable results: In 2024, 99.8% of shipments met all customer quality requirements, while maintaining 97% on-time delivery performance. These metrics reflect our dedication to precision manufacturing and customer satisfaction that has defined our company since 1989.

Key Performance Indicators

- Tolerances as tight as ±0.0005 inches

- 99.8% quality requirements consistently met

- Support for 13 aluminum alloy variations

- Lights-out manufacturing for maximum efficiency

Why Aluminum Excels in Precision Machining Applications

Aluminum stands as one of the most versatile materials in modern manufacturing, offering an exceptional combination of properties that make it ideal for precision machined components. The material’s excellent strength-to-weight ratio makes it particularly valuable in aerospace and automotive applications where weight reduction directly impacts performance and fuel efficiency.

Beyond mechanical properties, aluminum provides superior thermal and electrical conductivity, making it essential for electronics and heat management applications. The material’s natural corrosion resistance extends component life in demanding environments, while its high machinability enables the creation of complex geometries with tight tolerances that would be challenging or impossible with other materials.

For manufacturers seeking cost-effective solutions without compromising quality, aluminum offers an optimal balance. Its machinability characteristics allow for efficient production processes, particularly beneficial for high-volume manufacturing runs where consistency and repeatability are paramount.

Comprehensive Aluminum Machining Capabilities

Advanced CNC Turning Excellence

Our precision CNC turning operations leverage state-of-the-art equipment including 8-axis bar-fed turning centers capable of lights-out operation. This advanced automation ensures consistent quality while maximizing efficiency and reducing lead times for our customers.

Our turning capabilities accommodate bar stock up to 3 inches in diameter and slugs up to 10 inches in diameter, with maximum lengths reaching 20 inches. The precision achievable through our turning operations reaches tolerances as tight as ±0.0005 inches, making our services suitable for the most demanding applications in aerospace, medical, and precision instrument manufacturing.

The lights-out manufacturing approach allows our equipment to operate continuously, providing several advantages including improved consistency, reduced labor costs, and faster turnaround times. This capability is particularly valuable for medium to high-volume production runs where maintaining quality while meeting aggressive delivery schedules is critical.

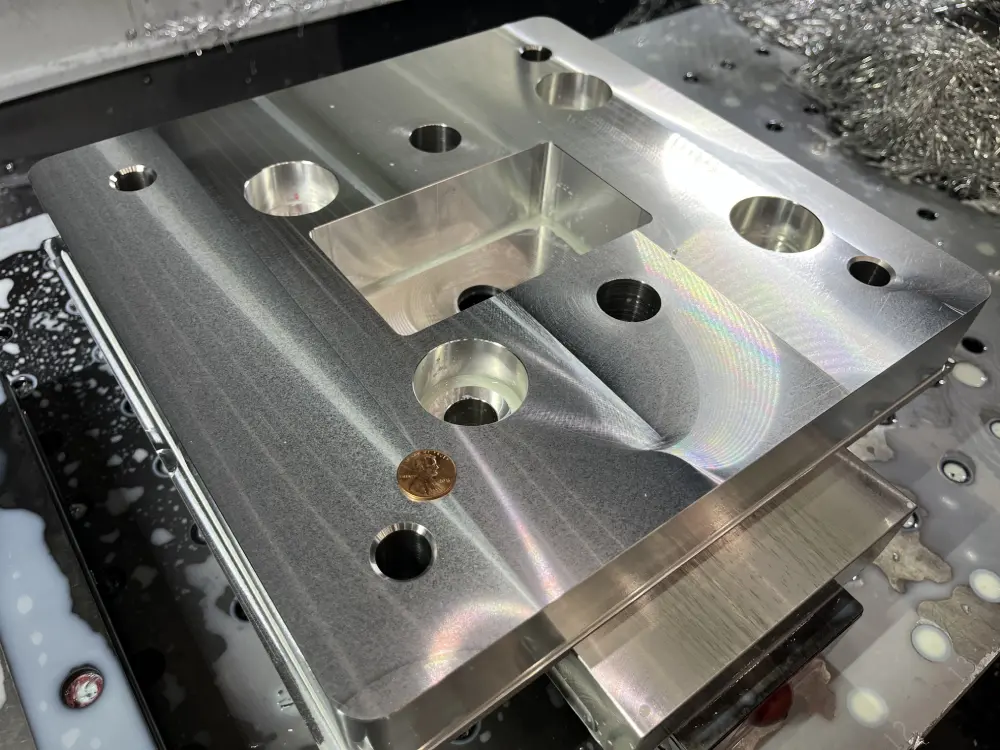

Precision CNC Milling Operations

Our horizontal and vertical machining centers offer comprehensive milling capabilities for aluminum components that require complex geometries and precise features. Equipment capabilities include 4-axis machining with 44-inch-long tables, a 330-tool capacity, and spindle speeds reaching 20,000 RPM, supported by 500 mm pallet systems.

These advanced machining centers enable us to handle aluminum components with complex three-dimensional geometries while maintaining the tight tolerances required for critical applications. The high spindle speeds and extensive tool capacity allow for efficient machining of difficult-to-machine aluminum alloys at optimal cutting parameters.

Our milling operations excel in producing manifolds, housings, brackets, and custom components where geometric complexity and dimensional accuracy are equally important. The combination of horizontal and vertical machining capabilities ensures optimal tool access and surface finish quality regardless of part geometry.

Swiss Machining for Complex Components

Swiss machining technology represents the pinnacle of precision manufacturing for small, complex aluminum components with high length-to-diameter ratios. Our Swiss machining centers feature up to 8-axis capability with live tooling, accommodating bar diameters up to 1.25 inches.

This manufacturing approach excels in producing intricate components that traditional machining methods would require multiple setups and operations to produce. The Swiss machining process maintains workpiece stability through guide bushing support, enabling exceptional precision and surface finish quality even on delicate components.

Swiss machining is particularly valuable for medical device components, aerospace fittings, and precision valve components, where dimensional accuracy and surface integrity are critical to component performance and safety.

Multi-Spindle Screw Machining Heritage

Hogge Precision maintains one of the few remaining multi-spindle screw machining capabilities in the Southeast, utilizing both single and multi-spindle CAM-operated machines. Our multi-spindle machines accommodate bar stock up to 2-1/4 inches in diameter, with maximum part lengths of 4 inches, and achieve tolerances of ±0.001 inches.

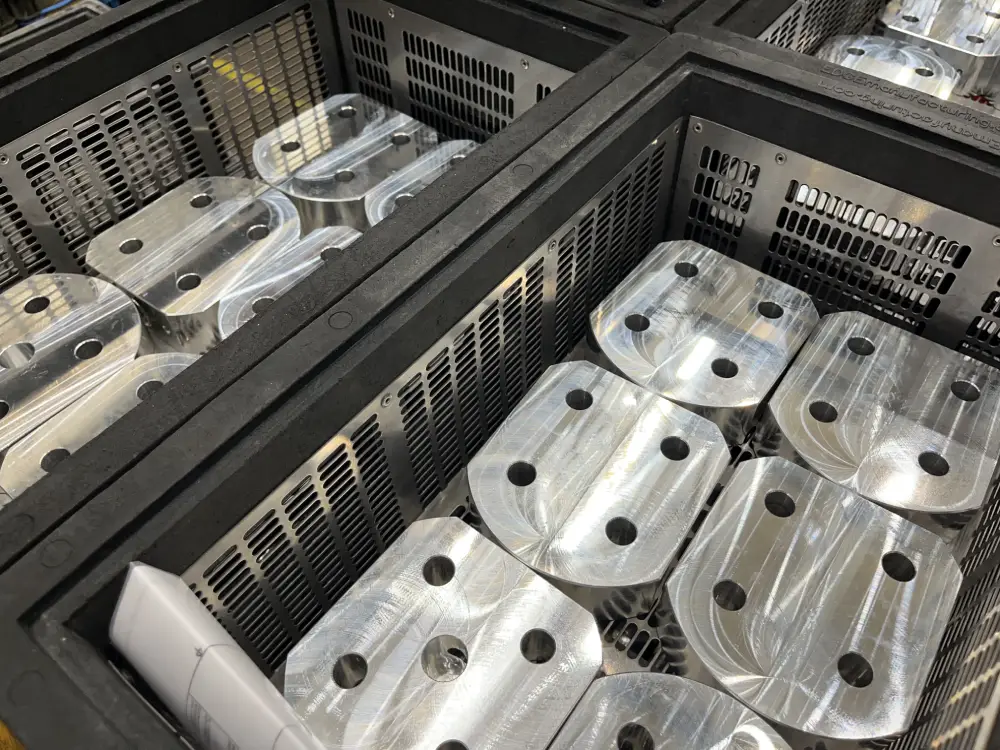

This capability is particularly valuable for high-volume production of standard and custom aluminum components where efficiency and consistency are paramount. The multi-spindle approach enables the simultaneous machining of multiple parts, significantly reducing the per-piece production time while maintaining quality standards.

Precision Standards and Quality Assurance

Achievable Precision and Tolerances

Our manufacturing capabilities consistently deliver standard precision tolerances of ±0.002 inches for most features, with high-precision operations achieving ±0.0005 inches for critical dimensions.

Quality achievement extends beyond dimensional accuracy to include surface finish control and geometric tolerancing. Our equipment and process capabilities enable us to meet complex geometric requirements, including concentricity, perpendicularity, and positional tolerances that are critical for assembly and function.

Quality Management System

Operating under ISO 9001:2015 certification, our quality management system ensures consistent processes and measurable results. In-process inspection utilizing coordinate measuring machines (CMM) and precision gaging provides real-time feedback and control throughout manufacturing operations.

Material certification and traceability documentation accompany every shipment, providing customers with comprehensive documentation for critical applications that require material pedigree verification. First article inspection capabilities ensure production runs meet specifications before full-scale manufacturing begins.

Advanced Manufacturing Technologies

Lights-Out Manufacturing Innovation

Our lights-out manufacturing capabilities represent a significant competitive advantage, enabling 24/7 automated production with minimal human intervention. This approach ensures consistent quality by eliminating human variables and reducing lead times through continuous operation.

Robotic loading and unloading systems minimize material handling while real-time monitoring ensures quality maintenance throughout extended production runs. This capability is particularly valuable for medium to high-volume production where consistency and efficiency directly impact project economics.

Multi-Task Machining Efficiency

Multi-task machining centers enable the complete production of parts in a single setup, reducing handling operations and improving dimensional accuracy by eliminating setup variations. Live tooling capabilities enable milling operations to be performed on turning centers, often eliminating the need for secondary operations entirely.

This integrated approach reduces lead times while improving quality through reduced part handling and setup variations. The result is more efficient production with improved dimensional consistency and reduced overall project costs.

Value-Added Services and Supply Chain Integration

Secondary Operations and Finishing

Our comprehensive secondary operations include heat treatment services such as annealing, hardening, and stress relief procedures. Surface finishing capabilities encompass Type I, II, and III anodizing, bead blasting, and polishing operations that enhance both function and appearance.

Additional coating services include powder coating, electroplating, and passivation treatments that provide enhanced corrosion resistance and environmental durability. Assembly services facilitate component integration and testing, delivering complete assemblies to customers rather than individual components.

Supply Chain Management Excellence

KANBAN inventory management systems offer just-in-time delivery capabilities, reducing customer inventory costs while ensuring material availability when needed. Custom packaging and labeling with barcode tracking enable seamless integration with customer receiving and inventory systems.

Blanket order capabilities allow customers to establish long-term supply agreements with scheduled releases, providing predictable supply costs and delivery schedules. Our 97% on-time delivery performance demonstrates consistent execution of these supply chain commitments.

Industry Applications and Project Examples

Aerospace and Defense Excellence

AS9100D certification demonstrates Hogge Precision’s commitment to meeting the stringent quality and process requirements demanded by the aerospace and defense industries. This certification, which builds upon our ISO 9001:2015 foundation, addresses the unique challenges of aerospace manufacturing, including risk management, configuration management, and product safety requirements.

Our aerospace and defense customers rely on our capabilities for critical flight components requiring exceptional dimensional accuracy and material integrity. The AS9100D standard ensures that our processes consistently meet the elevated quality expectations of aircraft manufacturers, defense contractors, and aerospace suppliers throughout the supply chain.

Complete material certification and traceability documentation support the stringent requirements of these demanding applications, providing customers with the documentation necessary for regulatory compliance and quality audits. Our understanding of aerospace manufacturing requirements extends beyond basic machining to encompass the complete quality framework that aerospace applications demand.

Medical Equipment Manufacturing

Medical equipment applications demand biocompatible aluminum components manufactured under controlled conditions with complete documentation. Our precision capabilities enable the manufacture of surgical instrument components and medical device housings, where dimensional accuracy directly impacts patient safety and device performance. Some example projects include medical gas systems and surgical tools.

Valve manifolds and control components represent core competencies where our aluminum machining expertise delivers reliable solutions for demanding pressure and flow control applications. We have pressure-tested assemblies capabilities to fit the needs of your project. Complex internal geometries and precise port locations ensure optimal fluid dynamics and system performance.

Featured Project Examples

Aluminum Safety Coupling Project: Working with a customer in the valve industry who experienced unsatisfactory results from their previous manufacturer, Hogge Precision employed precision CNC turning and milling capabilities to manufacture aluminum safety couplings that met strict tolerance requirements and quality standards. The successful project outcome led to ongoing monthly production for the satisfied customer.

Aluminum Medical Manifold for Air Compressor: Our horizontal milling capabilities enabled production of complex aluminum manifolds for air compressor applications, demonstrating our ability to handle intricate geometries while maintaining the dimensional accuracy required for proper fluid flow and system performance.

Design for Manufacturing Guidelines

Optimizing Aluminum Parts for Efficient Production

Successful aluminum machining projects begin with design considerations that optimize manufacturability while meeting functional requirements. We recommend a minimum 0.030″ wall thickness for our projects. Wall thickness considerations ensure adequate material stability during machining operations while maintaining structural integrity in service.

Corner radii specifications should consider both functional requirements and tool accessibility, with appropriate radii reducing stress concentrations while enabling efficient machining operations. Tolerance specifications should be applied judiciously, focusing on functionally critical dimensions while allowing standard tolerances for non-critical features.

Surface finish callouts should reflect actual application requirements, as unnecessary surface finish requirements increase production costs without functional benefit. Understanding the relationship between surface finish requirements and machining operations enables optimal specification that balances quality with cost-effectiveness.

Cost Optimization Strategies

Material selection should consider both functional requirements and machinability characteristics, with appropriate alloy selection enabling efficient production while meeting performance needs. Feature accessibility during machining operations significantly impacts production efficiency, with design considerations for tool access reducing setup complexity and machining time.

Volume considerations enable the leverage of our lights-out manufacturing capabilities for higher-volume applications, providing cost advantages through improved efficiency and reduced labor content. Secondary operation planning during the design phase can often combine operations or eliminate them through thoughtful design approaches.

Partnership and Project Initiation

Quote Request and Engineering Support

Our quote process begins with secure CAD file submission through our customer portal, followed by a comprehensive engineering review for manufacturability optimization. Detailed quotes include timeline projections and recommendations for design optimization when beneficial.

Production planning documentation and quality procedures are established before manufacturing begins, ensuring clear understanding of requirements and expectations.

Contact and Communication

Ready to discuss your precision aluminum machining requirements? Contact Hogge Precision Parts Co., Inc. at 843-332-3566 to speak directly with our engineering team about your project needs. Our experienced professionals are available to discuss material selection, design optimization, and production planning to ensure the success of your project.

Alternatively, submit your project requirements through our quote request system for comprehensive evaluation and recommendation. Our commitment to customer service and technical excellence ensures that your aluminum machining project receives the attention and expertise necessary for exceptional results.